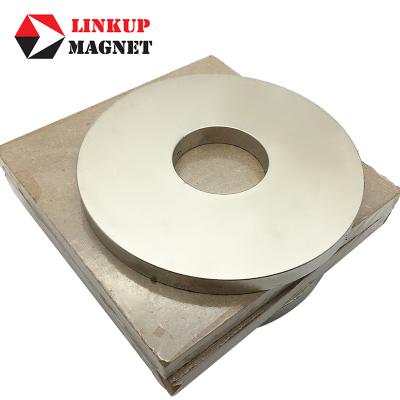

Features of XM51 Circular Permanent Magnetic Chuck

1. Can be installed on rotary grinding machine

2. High precision and powerful magnetic force,residual magnetism low.

3. Micropitch type suitable for smaller and thinner workpiece.

4. Fine pitch type best for larger and thicker workpiece.

5. Products can customize according to customer’s requirements.

6.The magnetic circuit orientation of circular permanent magnetic chuck can be designed as radial poles,straight dense pole.

Specifications of XM51 series - Circular Permanent Magnetic Chuck

| Model |

Diameter (mm) |

Height (mm) |

Suction Force (N/cm²) |

Pole Pitch |

Net Weight

(KG)

|

| XM51 160 | 160 | 48 | ≧ 80 |

0.5+1

or

3+1

|

9 |

| XM51 175 | 180 | 48 | ≧ 80 | 10 | |

| XM51 200 | 200 | 52 | ≧ 80 | 13 | |

| XM51 250 | 250 | 52 | ≧ 80 | 20 | |

| XM51 300 | 300 | 58 | ≧ 80 | 32 | |

| XM51 320 | 320 | 58 | ≧ 80 | 37 | |

| XM51 400 | 400 | 58 | ≧ 80 | 57 | |

| XM51 500 | 500 | 65 | ≧ 80 | 100 | |

| XM51 600 | 600 | 65 | ≧ 80 | 144 |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com