Features of XM43 Double Sine Plate Permanent Magnetic Chuck

1. Pole space is fine,Magnetic force is distributed uniformly.It performs well on thin and tiny workpiece machining.The working table precision doesn't change during magnetizing or demagnetizing.

2. The panel through special processing,with no leakage,prevents corrosion by cutting fluid,extends working life and enables to work longer time in cutting fluid.

3. Fine grinding on six faces.Can be used vertically in linear cutting machine.

4. The chuck with high performance magnetic steel,powerful magnetic force and almost no residual magnetism.

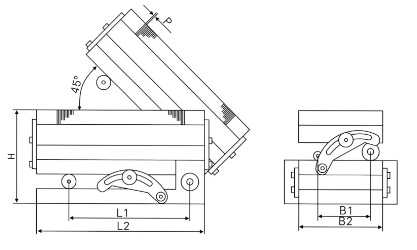

Specifications of XM43 Double Sine Plate Permanent Magnetic Chuck

| Model | L1 | L2 | H | B1 | B2 | P |

Tilting Degree |

Net Weight

(KG)

|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |||

| XM43 225x100 | 100 | 225 | 110 | 75 | 100 |

0.5+1.5

or

1+3

|

0°-45° | 13 |

| XM43 200x150 | 100 | 200 | 115 | 100 | 150 | 17 | ||

| XM43 300x150 | 150 | 300 | 115 | 100 | 150 | 35 | ||

| XM43 250x125 | 150 | 250 | 115 | 100 | 125 | 23 |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com