Sintered neodymium magnet is the most powerful rare earth magnet and have the widest range of applications. It is the best permanent magnet for magnetic applications requiring strong magnetic forces and max operating temperature resistance between 80℃ to 220℃.

They are widely used in electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields. The more common uses are permanent magnet motor, loudspeaker, magnetic separator, computer disk drive, magnetic resonance imaging equipment and instruments.

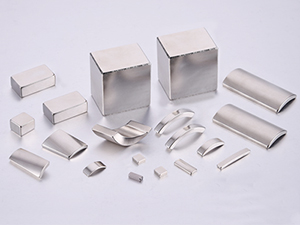

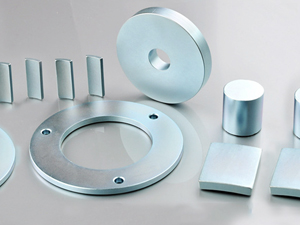

Typical products of sintered NdFeB magnet

Sintered neodymium magnets have good machinability,its size can be customized and processed into the block,disc,ring,arc,sphere,cylindrical,trapezoidal or irregular shapes.

|

|

|

|

|

|

|

|

|

| Featured products of sintered NdFeB magnet |

- Radial oriented sintered neodymium ring magnet OD from 20 mm to 75 mm, ID from 15mm to 68mm, height from 5 mm to 50 mm;

- Low deviation angle magnet can meet the requirement of magnetic deviation angles ≤ ±3°;

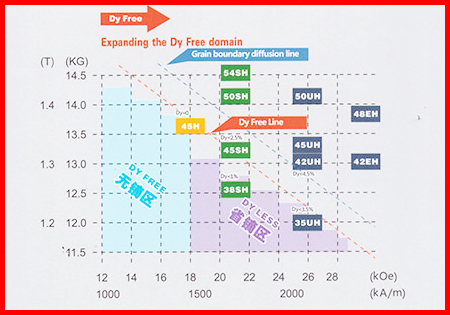

- Dy free and Grain boundary diffusion process help to lower the use of heavy rare earth and obvious increase of coercive force and higher working temperature for magnets;

- Low weight loss magnet can be provided according to customer requirements, the loss weight ≤1.0 mg/cm2 under 132 deg. c. P:3atm and RH100T conditions;

- Low temperature coefficient magnet improved the temperature resistance ability,which get better thermo stabilization and less demagnetization in the same grade. The αBr is -0.2 ~ -0.12 %/℃ and the βHcJ is -0.38 ~ -0.8 %/℃;

|

|

|

|

|

|

Radial oriented ring magnet, it’s widely |

|

|

Grain boundary diffusion (GBD) process to |

| Properties of sintered NdFeB magnet |

| Series | Grade | Max Operating Temp. ℃ |

Remanence Br

mT(KG)

|

Coercivity Hcb

KA/m(KOe)

|

Intrinsic Coercivity Hcj

KA/m(KOe)

|

Maximium Energy Product

(BH)max KJ/m3 (MGOe)

|

| N | N35 | ≤80℃ | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥955(≥12) | 263-287(33-36) |

| N38 | ≤80℃ | 1220-1250(12.2_12.5) | ≥899(≥11.3) | ≥955(≥12) | 287-310(36-39) | |

| N40 | ≤80℃ | 1250-1280(12.5-12.8) | ≥907(≥11.4) | ≥955(≥12) | 302-326(38-41) | |

| N42 | ≤80℃ | 1280-1320(12.8-13.2) | ≥915(≥11.5) | ≥955(≥12) | 318-342(40-43) | |

| N45 | ≤80℃ | 1320-1380(13.2-13.8) | ≥923(≥11.6) | ≥955(≥12) | 342-366(43-46) | |

| N48 | ≤80℃ | 1380-1420(13.8-14.2) | ≥923(≥11.6) | ≥955(≥12) | 366-390(46-49) | |

| N50 | ≤80℃ | 1400-1450(14.0-14.5) | ≥836(≥10.5) | ≥955(≥12) | 382-406(48-51) | |

| N52 | ≤80℃ | 1430-1480(14.3-14.8) | ≥836(≥10.5) | ≥876(≥11) | 398-422(50-53) | |

| N54 | ≤80℃ | 1450-1490(14.5-14.9) | ≥836(≥10.5) | ≥876(≥11) | 406-438(51-55) | |

| N55 | ≤80℃ | 1470-1520(14.7-15.2) | ≥836(≥10.5) | ≥876(≥11) | 414-438(52-56) | |

| M | 35M | ≤100℃ | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥1114(≥14) | 263-287(33-36) |

| 38M | ≤100℃ | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥1114(≥14) | 287-310(36-39) | |

| 40M | ≤100℃ | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥1114(≥14) | 302-326(38-40) | |

| 42M | ≤100℃ | 1280-1320(12.8-13.2) | ≥955(≥12.0) | ≥1114(≥14) | 318-342(40-43) | |

| 45M | ≤100℃ | 1320-1380(13.2-13.8) | ≥955(≥12.5) | ≥1114(≥14) | 342-366(43-46) | |

| 48M | ≤100℃ | 1360-1430(13.6-14.3) | ≥1027(≥12.9) | ≥1114(≥14) | 366-390(46-49) | |

| 50M | ≤100℃ | 1400-1450(14.0-14.5) | ≥1033(≥13.0) | ≥1114(≥14) | 382-406(48-51) | |

| 52M | ≤100℃ | 1420-1460(14.2-14.6) | ≥1033(≥13.0) | ≥1114(≥14) | 398-414(50-52) | |

| 54M | ≤100℃ | 1450-1490(14.5-14.9) | ≥1051(≥13.2) | ≥1114(≥14) | 406-438(51-55) | |

| H | 35H | ≤120℃ | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥1353(≥17) | 263-287(33-36) |

| 38H | ≤120℃ | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥1353(≥17) | 287-310(36-39) | |

| 40H | ≤120℃ | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥1353(≥17) | 302-326(38-41) | |

| 42H | ≤120℃ | 1280-1320(12.8-13.2) | ≥955(≥12.0) | ≥1353(≥17) | 318-342(40-43) | |

| 45H | ≤120℃ | 1300-1360(13.0-13.6) | ≥963(≥12.1) | ≥1353(≥17) | 326-358(43-46) | |

| 48H | ≤120℃ | 1370-1430(13.7-14.3) | ≥955(≥12.5) | ≥1353(≥17) | 366-390(46-49) | |

| 50H | ≤120℃ | 1400-1450(14.0-14.5) | ≥955(≥12.5) | ≥1353(≥17) | 382-406(48-51) | |

| 52H | ≤120℃ | 1420-1460(14.2-14.6) | ≥1043(≥13.1) | ≥1353(≥17) | 390-422(49-53) | |

| 54H | ≤120℃ | 1440-1490(14.4-14.9) | ≥1043(≥13.1) | ≥1353(≥17) | 398-438(50-55) | |

| SH | 35SH | ≤150℃ | 1170-1220(11.7-12.2) | ≥876(≥11.0) | ≥1592(≥20) | 263-287(33-36) |

| 38SH | ≤150℃ | 1220-1250(12.2-12.5) | ≥907(≥11.4) | ≥1592(≥20) | 287-310(36-39) | |

| 40SH | ≤150℃ | 1240-1280(12.5-12.8) | ≥939(≥11.8) | ≥1592(≥20) | 302-326(38-41) | |

| 42SH | ≤150℃ | 1280-1320(12.8-13.2) | ≥987(≥12.4) | ≥1592(≥20) | 318-342(40-43) | |

| 45SH | ≤150℃ | 1320-1380(13.2-13.8) | ≥1003(≥12.6) | ≥1592(≥20) | 342-366(43-46) | |

| 48SH | ≤150℃ | 1370-1430(13.7-14.3) | ≥1011(≥12.7) | ≥1592(≥20) | 358-390(45-49) | |

| 50SH | ≤150℃ | 1400-1450(14.0-14.5) | ≥1003(≥12.6) | ≥1592(≥20) | 374-406(47-51) | |

| 52SH | ≤150℃ | 1420-1460(14.2-14.6) | ≥1003(≥12.6) | ≥1592(≥20) | 392-422(49-53) | |

| 54SH | ≤150℃ | 1440-1490(14.4-14.9) | ≥1003(≥12.6) | ≥1592(≥20) | 398-430(50-54) | |

| UH | 30UH | ≤180℃ | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥1990(≥25) | 223-247(28-31) |

| 33UH | ≤180℃ | 1130-1170(11.3-11.7) | ≥852(≥10.7) | ≥1990(≥25) | 247-271(31-34) | |

| 35UH | ≤180℃ | 1180-1220(11.8-12.2) | ≥860(≥10.8) | ≥1990(≥25) | 263-287(33-36) | |

| 38UH | ≤180℃ | 1220-1250(12.2-12.5) | ≥876(≥11.0) | ≥1990(≥25) | 287-310(36-39) | |

| 40UH | ≤180℃ | 1240-1280(12.4-12.8) | ≥899(≥11.3) | ≥1990(≥25) | 302-326(38-41) | |

| 42UH | ≤180℃ | 1280-1320(12.8-13.2) | ≥899(≥11.3) | ≥1990(≥25) | 318-342(40-43) | |

| 45UH | ≤180℃ | 1320-1380(13.2-13.8) | ≥899(≥11.3) | ≥1990(≥25) | 334-358(42-45) | |

| 48UH | ≤180℃ | 1370-1430(13.7-14.3) | ≥1011(≥12.7) | ≥1990(≥25) | 358-390(45-49) | |

| 50UH | ≤180℃ | 1400-1450(14.0-14.5) | ≥1035(≥13.0) | ≥1990(≥25) | 374-406(47-51) | |

| EH | 28EH | ≤200℃ | 1040-1090(10.4-10.9) | ≥780(≥9.8) | ≥2388(≥30) | 207-231(26-29) |

| 30EH | ≤200℃ | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥2388(≥30) | 223-247(28-31) | |

| 33EH | ≤200℃ | 1130-1170(11.3-11.7) | ≥836(≥10.5) | ≥2388(≥30) | 247-271(31-34) | |

| 35EH | ≤200℃ | 1170-1220(11.7-12.2) | ≥876(≥11.0) | ≥2388(≥30) | 263-287(33-36) | |

| 38EH | ≤200℃ | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥2388(≥30) | 287-310(36-39) | |

| 40EH | ≤200℃ | 1240-1280(12.4-12.8) | ≥939(≥11.6) | ≥2388(≥30) | 302-326(38-41) | |

| 42EH | ≤200℃ | 1280-1320(12.8-13.2) | ≥939(≥11.6) | ≥2388(≥30) | 320-340(38-41) | |

| 45EH | ≤200℃ | 1320-1380(13.2-13.8) | ≥979(≥12.3) | ≥2388(≥30) | 342-366(43-46) | |

| 48EH | ≤200℃ | 1370-1430(13.7-14.3) | ≥979(≥12.3) | ≥2388(≥30) | 358-390(45-49) | |

| AH | 30AH | ≤220℃ | 1020-1080(10.2-10.8) | ≥804(≥10.1) | ≥2624(≥33) | 223-239(28-30) |

| 33AH | ≤220℃ | 1140-1170(11.4-11.7) | ≥844(≥10.6) | ≥2624(≥33) | 247-263(31-33) | |

| 35AH | ≤220℃ | 1170-1210(11.7-12.1) | ≥876(≥10.9) | ≥2624(≥33) | 263-279(33-36) | |

| 38AH | ≤220℃ | 1220-1250(12.2-12.5) | ≥876(≥10.9) | ≥2624(≥33) | 279-310(36-39) | |

| 40AH | ≤220℃ | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥2624(≥33) | 302-326(38-41) | |

| 42AH | ≤220℃ | 1280-1320(12.8-13.2) | ≥931(≥11.7) | ≥2624(≥33) | 318-342(40-43) | |

| 45AH | ≤220℃ | 1320-1380(13.2-13.8) | ≥932(≥11.7) | ≥2624(≥33) | 342-366(43-46) |

|

Download PDF file of properties of sintered NdFeB magnet |

|

Note: |

|

1. The above - mentioned data of magnetic parameters and physical properties are given at room temperature. |

|

2. Grain boundary diffusion (GBD) process for 54SH, 50UH, 48EH, 45AH,required thickness of magnet less than 5 mm. |

|

3. Grain boundary diffusion (GBD) process for 52SH, 50SH, 48UH, 45Uh, 45EH, 42EH, 42AH, 40AH, required thickness of magnet less than 8 mm. |

| Application fields of different grades of sintered NdFeB magnet for reference |

| 1. Industrial motor applications |

|

|

|

|

Used in Servo motor, Brushless motor, Linear Motor, Automotive Motor, HEV& EV motor, Robot Driving Motor, Inverter Compressor Motor, Rail Transit Traction Motor, Wind turbine, Energy-saving Elevator motor, Permanent magnet traction motor, VCM etc.

Recommend grade of sintered NdFeB magnet: 50M, 50H, 35SH, 38SH, 48SH, 28UH, 30UH, 33UH, 35UH, 38UH, 45UH, 33EH, 35EH, 42EH, 35AH, 38AH etc.

|

Used in Consumer Electronics, Cell Phone, Computer, Ipad, Iwatch, Unmanned aerial vehicle etc.

Recommend grade of sintered NdFeB magnet:N35, N42, N50, N52, 45M, 48M, 50M, 42H, 45H, 48H, 50H, 38SH, 42SH, 38UH etc.

2. Consumer electronics applications

|

|

3. Automobile applications |

|

|

|

|

|

|

Used in EPS, Pump Motor, Starter Motor , Roof Motor, ABS sensor, Ignition Coil, Loudspeakers etc.

Recommend grade of sintered NdFeB magnet: 35M, 45H, 48H, 38SH, 40SH, 42SH, 48SH, 30UH, 33UH, 35UH, 35EH, 38EH etc.

|

|

|

4. Acoustic component applications |

|

|

|

|

|

|

Used in Loudspeaker, Acoustic component, Consumer electronics etc.

Recommend grade of sintered NdFeB magnet: N35, N38, N50, N52, 42M, 45M, 50M, 35H, 38H, 40H, 42H, 48H,50H etc.

|

Available coating of sintered NdFeB magnet

| Coating | Thickness | Clor | Bond Strength | Insulation | SST | Characteristic |

| Cr3+Zn | 4-8 μm | Bright Blue | Good | Bad | >24H~48H | Regular Protection,Applicable to most products |

| Colored Zn | 4-8 μm | Shining Color | Good | Bad | >48H~72H | Excellent salt spray resistance |

| NiCuNi | 10-20 μm | Bright Silver | Good | Bad | >24H~72H | Excellent humidity,heat & salt spray resistance,High temperature resistance. |

| NiCuNi+Cr | 10-25 μm | Bright Silver | Good | Bad | >48H~72H | |

| NiCuNi+Sn | 10-25 μm | Silver | Good | Bad | >48H~72H | |

| Electroless Nickel | 4-8 μm | Silver | Good | Bad | >92H | |

| Phosphating +Epoxy | 10-20 μm | Black or Gray | Excellent | Excellent | >168H | Excellent humidity,heat & salt spray resistance;Excellent adhesion;Excellent Insulation |

| NiCu+Epoxy | 10-20 μm | Black or Gray | Excellent | Excellent | >168H | Excellent humidity,heat & salt spray resistance;Excellent adhesion;Excellent Insulation |

| Sprayed Epoxy | 10-30 μm | Black or Gray | General | Excellent | >72H | Excellent humidity,heat & salt spray resistance;Excellent Insulation |

| Phosphated/Passivation | 1-3 μm | Dark Grey | Excellent | Poor | <2.5H | Temporary Protection |

| Everlube | 8-20 μm | Yellow | Good | Excellent | >24H | Excellent Ssalt spray resistance |

| Teflon | >10 μm | Black or Blue | Good | Excellent | >16H | Excellent fricction resistance; High/low temp resistance;Anti-corrosion; Acid and alkali resistant; |

| NiCuNi+Au | 10-15 μm | Golden | Good | Bad | >12H | Good looking |

| Parylene | 6-12 μm | Transparent | Good | Excellent | >24H | Good electrical insulation; Moisture-proof; Anti-corrosion and anti salt spray are excellent; |

|

|

|

|

NiCUNi

|

Cr3+Zn

|

Black Epoxy

|

|

|

|

|

NiCuNi+Au

|

NiCuNi+Cr

|

Everlube

|

|

|

|

|

Phosphated

|

Teflon

|

|

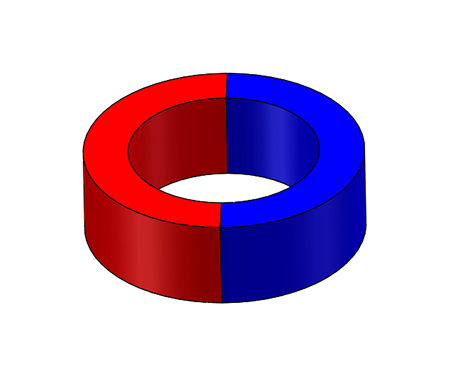

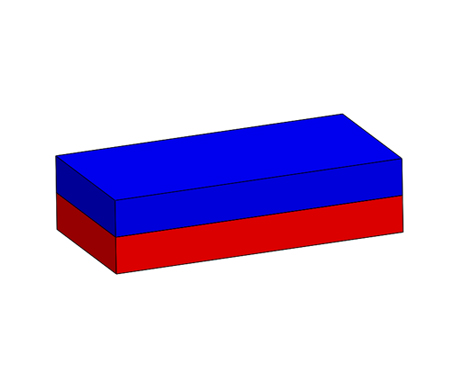

| Direction of magnetization |

|

|

|

|

|

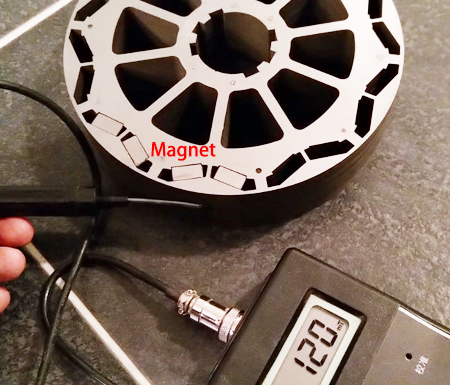

| Diameterical magneitzed neodymium magnet ring used for motor axis,with a minimum force of 1.2 Tesla. |

|

|

|

|

|

| N42UH block neodymium magnet, magnetized through thickness and NiCuNi coated, be used for the motor. The magnet was tested at a temperature of 100 degrees Celsius, no permanent demagnetization occurred. Even the field drooped to 18uT from 26uT at 20cm distance. After cooling they regain the strength. |

|

|

|

|

|

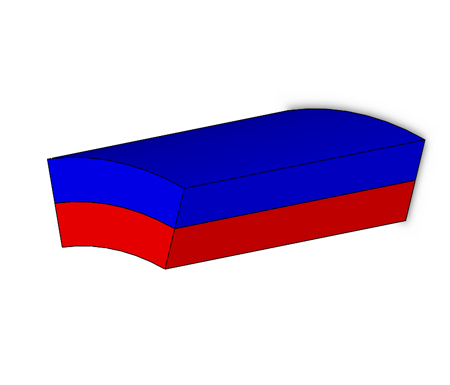

| Arc neodymium magnet with diametrical paired magnetized are widely used for motor rotor,magnetic coupling and etc. |

|

|

|

|

|

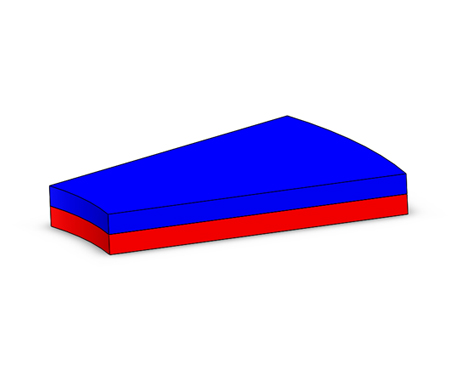

| Fan trapezoidal neodymium magnet magnetic through thickness, be used for VCM and other motor. |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com