Linkup Magnet fabricate sintered neodymium magnets,samarium cobalt magnets,alnico magnets,ferrite magnets,flexible magnet and bonded neodymium magnets to your specific requirements.

|

|

|

|

|

|

There are differences in the varieties and grades of magnetic alloy materials.Each permanent magnet material has its own unique advantages and disadvantages.We recommend that you contact our sales specialist in order to review your application. We will then be able to select the right magnetic material for your application.

A brief description of commercially available magnet materials is listed below. More rigorous explanations and technical properties of the various magnet materials can be found on their individual pages.

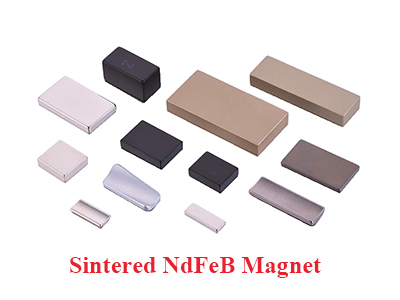

Neodymium magnet is a rare-earth magnet composed of Neodymium Iron and Boron and is moderate in price.NdFeB magnets with poor corrosion resistance are usually electroplated or coated (such as nickel plating,epoxy coating). Neodymium magnets are available in a range of operating temperature ranges depending on your application (80°C to 220°C). High grade neodymium magnet capable of operating above 120°C can become expensive.This magnetic material is extremely powerful that it can shrink the size of many products,from HDDs (Hard Disk Drives) and motors to novelties and audio devices.Neodymium permanent magnets generally offer the best value when comparing price and performance.

Samarium Coablt Magnet

Samarium cobalt magnet is another rare earth magnet,mainly composed of largely of cobalt and samarium,and is the most expensive magnetic material to manufacture.Most of the cost is due to the high cobalt content and the brittleness of samarium alloys.This permanent magnet material has high corrosion resistance and can withstand high temperature operation up to 350°C. Samarium cobalt magnetic materials are widely used in aerospace markets or industrial fields where performance is a priority and cost is a secondary concern.Samarium cobalt magnet is the second most powerful magnet material,with excellent resistance to demagnetization.

Alnico Magnet

Alnico magnet are mainly composed of aluminum,iron,cobalt and nickel. Alnico is an moderately expensive magnet material due to its cobalt and nickel content.AlNiCo magnet have a high maximum operating temperature and very good corrosion resistance. Certain grades of AlNiCo magnet can operate at temperatures 500°C-550°C. Alnico magnets are available in a variety of grades and sizes and are usually cast and finished to size. Alnico magnet material is an older technology with a rather low energy product (BHmax). Alnico magnet are now primarily used in military,aerospace,and applications where the magnets will be exposed to high temperatures.

Ferrite Magnet

Ferrite magnet (Ceramic magnet) is strontium ferrite.Ferrite magnets are one of the most cost-effective magnetic materials to manufacture. The low cost is due to the cheap,abundant and non-strategic raw materials used to make this alloy. Ferrite magnets lend themselves to large productions runs. Ferrite magnet has good corrosion resistance and can work in moderate heat. Most of the world's ferrite magnet come from China due to the commodity nature of alloys. Ferrite magnets have a low energy product and are often used in assemblies containing mild steel.

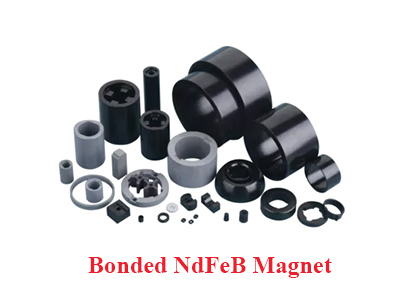

Bonded Neodymium Magnet

Bonded neodymium magnet can be composed of NdFeB powders combined with various plastic binders (matrix).It can be injection molded or compression bonded into complex magnet shapes with finished dimensions.The bonded magnet material has moderate corrosion resistance and low heat resistance due to the binder material.Bonded magnets are often used in automotive parts because they are suitable for high volume production and complex shapes can be produced at low cost.

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com