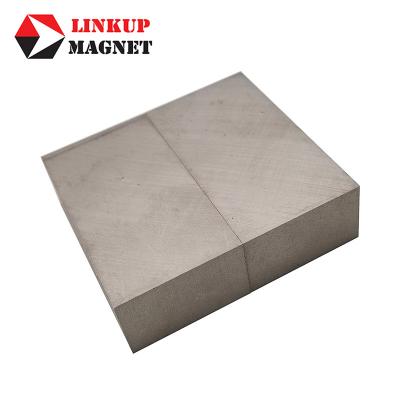

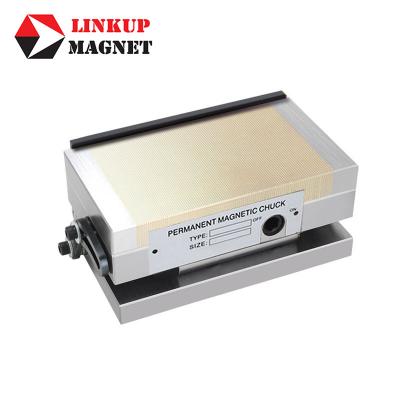

Widely used for processing various CNC machining centers and milling machine precisely and in high speed. Make it possible to clamp and fix quickly, one time clamping and fixing can finish processing five surfaces.

Features of XCM91 Grids Super-Powerful Permanent Magnetic Chuck

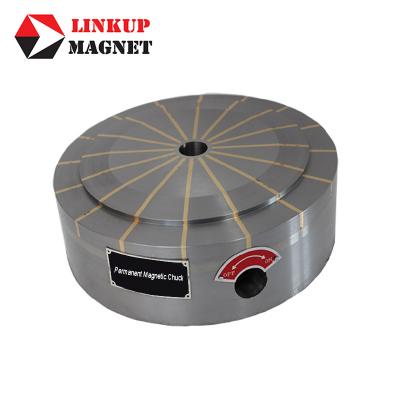

1. Produce strong magnetic force, no power consumption, no heat, simple and practical.

2. Can be used for strong milling,drilling,the force can be increased with the increasing contact area of the workpiece.

3. Large rigidity, strong stability,can not be deformed and can realize precision machining.

4. Simple mechanical on-off switch,no need power supply.

5. To achieve five-side machining,signiflcantly improve the efficiency by 80%.

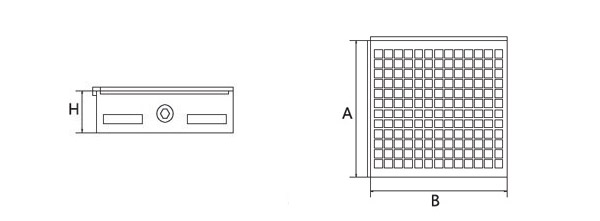

Specifications of XCM91 Grids Super-Powerful Permanent Magnetic Chuck

| Model | Dimensions(mm) |

Grids Dimensions

(mm)

|

Pole Number |

Net Weight

(KG)

|

Magnetic Force | ||

| W | L | H | |||||

| XCM91 2040 | 200 | 400 | 60 | 18×18 | 105 | 30 | 240 N/cm² |

| XCM91 3040 | 300 | 400 | 60 | 18×18 | 165 | 45 | |

| XCM91 3030 | 300 | 300 | 90 | 18×18 | 132 | 55 | |

| XCM91 4040 | 400 | 400 | 90 | 18×18 | 240 | 94 | |

| XCM91 4050 | 400 | 500 | 90 | 18×18 | 300 | 110 | |

| XCM91 3060 | 300 | 600 | 90 | 18×18 | 264 | 90 | |

| XCM91 4060 | 400 | 600 | 90 | 18×18 | 360 | 125 | |

| XCM91 5050 | 500 | 500 | 110 | 18×18 | 400 | 120 | |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com