| How to choose SmCo5 magnet and Sm2Co17 magnets |

The maximum energy product [BH(max)] range of SmCo5 magnet is between 16 MGOe ~ 25 MGOe, and the maximum working temperature is 250°C. Although, the maximum energy product [BH(max)] of SmCo5 magnet is lower than that of Sm2Co17 magnet, but the mechanical properties and ductility are better than Sm2Co17 magnet, and it is easier to machine. The SmCo5 magnet is not as brittle as Sm2CO17 magnet when used, so SmCo5 magnets are suitable for processing into shapes and specifications that Sm2Co17 magnets are not easy to process. For example, disc, block, ring magnets with extremely thin thickness or walls and various complex irregularl shape magnets.

The maximum energy product [BH(max)] range of Sm2CO17 is between 20 MGOe ~ 35 MGOe, and the maximum working temperature is 350°C. Because Sm2Co17 has a lower temperature coefficient and better corrosion resistance, its magnetic performance exceeds that of NdFeB magnets at high temperatures, so it is widely used in aerospace, military fields, high-temperature motors, automotive sensors, and various magnetic drives, magnetic pumps and microwave devices and other fields.

| Typical product specification of sintered samarium cobalt magnet |

|

Blocks & Bars |

|

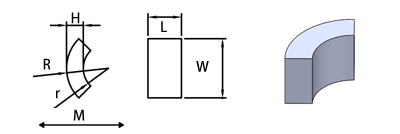

Segment or Arc | ||

| L | 1-200mm | W | 3-100mm | ||

| W | 0.5-100mm | H | 1-100mm | ||

| H | 0.3-120mm | L | 1-120mm | ||

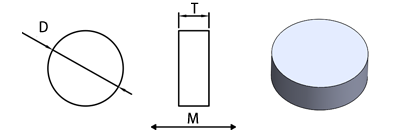

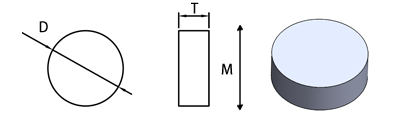

Discs & Rods

Axial Magneitzed

Discs $ Rods

Diametrical Magnetized

D

1-130mm

D

1-120mm

T

0.3-100mm

T

0.3-100mm

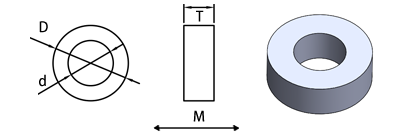

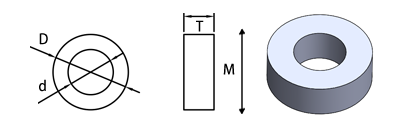

Ring & Hollow Cylinder

Axial Magnetized

Rring & Hollow Cylinder

Diametrical Magnetized

D

1.2-120mm

D

1.2-120mm

d

0.3-90mm

d

0.3-80mm

T

0.3-60mm

T

0.3-130mm

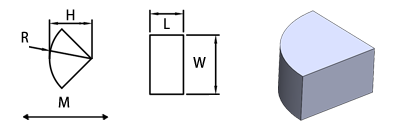

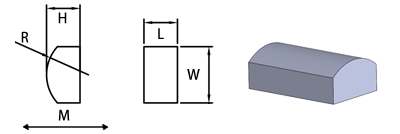

Fen - Shaped

Bread- Shaped

W

3-100mm

W

3-100mm

H

1.5-100mm

H

1-100mm

L

1-100mm

L

1-100mm

Technological Advantages:

1. The largest block size can reach 130mm×130mm×100mm, and can achieve full saturation magnetization.

2. Produce planar multi-pole samarium cobalt magnets, and the magnetization thickness generally cannot exceed 6mm.

3. Produce SmCo magnets with magnetization deviation within 1° (for magnetizing products).

4. Produce a variety of complex shapes and multi-angle magnetized samarium-cobalt magnet components, such as halbeck array, magnetron, magnetic assembly for plasma source.

Properties of sintered samarium cobalt magnet

Grade

Maximum Energy Product (BH)max

Max Working Temp. (Tw)

T

KGS

KA/m

kOe

KA/m

kOe

kJ/m³

MGOe

℃

%/°C

%/°C

SmCo5

YX16

0.81-0.85

8.1-8.5

610-660

7.8-8.3

1194-1830

15-23

111-127

14-16

250

-0.05

-0.3

YX18

0.85-0.90

8.5-9.0

650-700

8.3-8.8

1194-1830

15-23

127-143

16-18

250

-0.05

-0.3

YX20

0.90-0.94

9.0-9.4

680-725

8.5-9.1

1194-1830

15-23

143-159

18-20

250

-0.05

-0.3

YX22

0.94-0.96

9.4-9.6

710-750

8.9-9.4

1194-1830

15-23

159-175

20-22

250

-0.05

-0.3

YX24

0.96-1.00

9.6-10.0

720-770

9.2-9.7

1194-1830

15-23

175-190

22-24

250

-0.05

-0.3

YX16S

0.79-0.84

7.9-8.4

612-660

7.7-8.3

≥1830

≥23

118-135

15-17

250

-0.035

-0.28

YX18S

0.84-0.90

8.4-9.0

644-692

8.1-8.7

≥1830

≥23

135-151

17-19

250

-0.04

-0.28

YX20S

0.90-0.94

9.0-9.4

684-732

8.6-9.2

≥1830

≥23

151-167

19-21

250

-0.045

-0.28

YX22S

0.92-0.96

9.2-9.6

710-756

8.9-9.5

≥1830

≥23

167-183

21-23

250

-0.045

-0.28

YX24S

0.96-1.00

9.6-10.0

740-788

9.3-9.9

≥1830

≥23

183-199

23-25

250

-0.045

-0.28

Sm2Co17

YXG22H

0.93-0.97

9.3-9.7

676-740

8.5-9.3

≥1990

≥25

160-175

20-22

300

-0.02

-0.2

YXG24H

0.95-1.02

9.5-10.2

700-750

8.7-9.4

≥1990

≥25

175-191

22-24

350

-0.025

-0.2

YXG26H

1.02-1.05

10.2-10.5

750-780

9.4-9.8

≥1990

≥25

191-207

24-26

350

-0.03

-0.2

YXG28H

1.05-1.08

10.5-10.8

756-796

9.5-10

≥1990

≥25

207-220

26-28

350

-0.035

-0.2

YXG30H

1.08-1.10

10.8-11.0

788-835

9.9-10.5

≥1990

≥25

220-240

28-30

350

-0.035

-0.2

YXG32H

1.10-1.13

11.0-11.3

812-860

10.2-10.8

≥1990

≥25

230-255

29-32

350

-0.035

-0.2

YXG22

0.93-0.97

9.3-9.7

676-740

8.5-9.3

≥1443

≥18

160-175

20-22

300

-0.02

-0.2

YXG24

0.95-1.02

9.5-1.02

692-764

8.7-9.6

≥1443

≥18

175-191

22-24

300

-0.025

-0.2

YXG26

1.02-1.05

10.2-10.5

748-796

9.4-10.0

≥1443

≥18

191-207

24-26

300

-0.03

-0.2

YXG28

1.05-1.08

10.5-10.8

756-812

9.5-10.2

≥1443

≥18

207-220

26-28

300

-0.035

-0.2

YXG30

1.08-1.10

10.8-11.0

788-835

9.9-10.5

≥1443

≥18

220-240

28-30

300

-0.035

-0.2

YXG32

1.10-1.13

11.0-11.3

812-860

10.2-10.8

≥1443

≥18

230-255

29-32

300

-0.035

-0.2

YXG26M

1.02-1.05

10.2-10.5

676-780

8.5-9.8

955-1433

12-18

191-207

24-26

300

-0.035

-0.2

YXG28M

1.05-1.08

10.5-10.8

676-796

8.5-10.0

955-1433

12-18

207-220

26-28

300

-0.035

-0.2

YXG30M

1.08-1.10

10.8-11.0

676-835

8.5-10.5

955-1433

12-18

220-240

28-30

300

-0.035

-0.2

YXG28L

1.05-1.08

10.5-10.8

541-764

6.8-9.6

636-955

8-12

207-220

26-28

250

-0.035

-0.2

YXG30L

1.08-1.15

10.8-11.5

541-796

6.8-10.0

636-955

8-12

220-240

28-30

250

-0.035

-0.2

YXG32L

1.10-1.15

11.0-11.5

541-812

6.8-10.2

636-955

8-12

230-255

29-32

250

-0.035

-0.2

Technological Advantages:

Download PDF file of properties of sintered samarium cobalt magnet

1. Customize ultra-low temperature coefficient Sm2Co17 magnets. Under the condition of RT-100°C, the temperature coefficient of Br is -0.001%/°C.

2. Customize high temperature resistant Sm2Co17 magnets, the maximum working temperature can reach 400°C, 450°C, 500°C.

3. Customize ultra-high energy Sm2CO17 magnets, Br up to 11.6-12kGs and (BH)max up to 32-35MGOe.

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com