The holding force is 100-120 N/cm2.

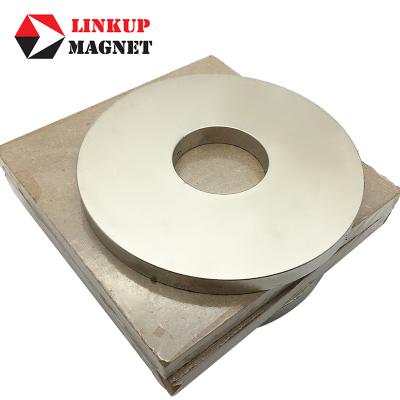

Features of X21 series -Circular electromagnetic chuck

1. Suction force well-distributed

2. Position reliable

3. Easy to operate

4. Improve the processing efficiency by more than 80%

Specifications of X21 series - Circular electromagnetic chuck

| Model | Diameter (mm) |

Height

(mm)

|

Rated Voltage

(V)

|

Net Weight

(KG)

|

| X21 310 | 310 | 97 | 110 | 38 |

| X21 320 | 320 | 105 | 110 | 40 |

| X21 400 | 400 | 105 | 110 | 90 |

| X21 500 | 500 | 107 | 110 | 136 |

| X21 630F | 630 | 133 | 110 | 280 |

| X21 780 | 780 | 180 | 110 | 500 |

| X21 800 | 800 | 180 | 110 | 650 |

| X21 1000 | 1000 | 156 | 110 | 1250 |

| X21 1250 | 1250 | 190 | 110 | 2000 |

| X21 1600 | 1600 | 245 | 110 | 3700 |

| X21 1800 | 1800 | 245 | 110 | 5000 |

| X21 2000 | 2000 | 240 | 110 | 5600 |

| X21 2250 | 2250 | 240 | 110 | 6600 |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com