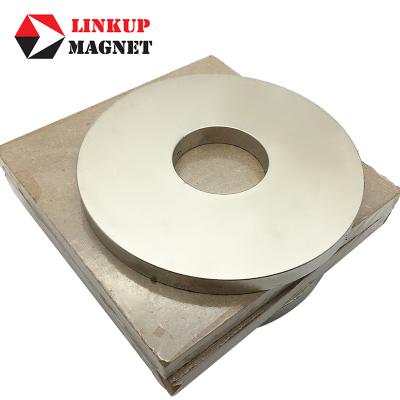

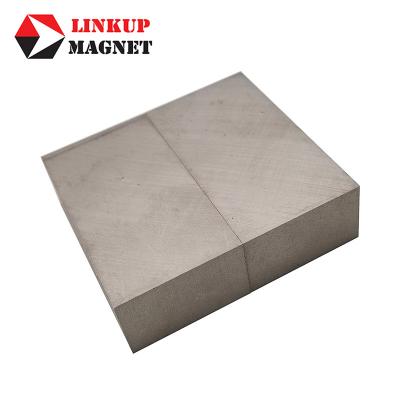

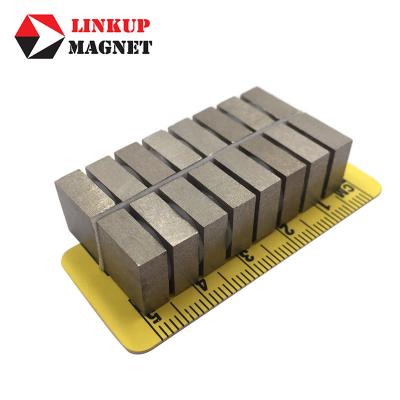

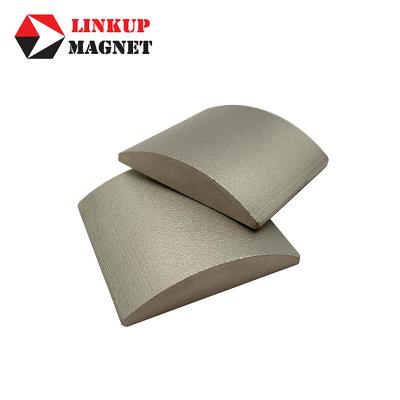

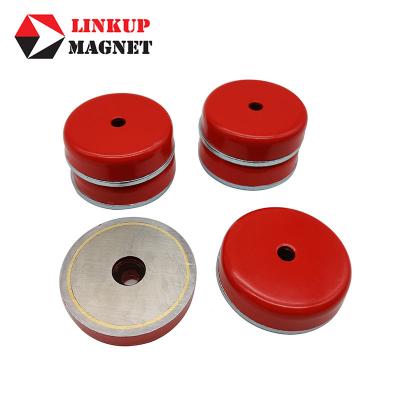

Samarium cobalt magnet typically fall into two families of materials,SmCo5 and Sm2Co17.It offers good magnetic and thermal stability and excellent corrosion resistance.The highest working temperature of SmCo magnet can reach up to 350 centigrade,which makes it very suitable for the manufacturing of high performance permanent magnet motors and some environment sensitive products.

Samarium cobalt magnets are the second most magnetic material today.

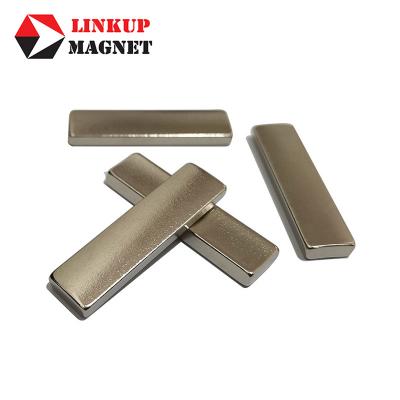

Advantage of SmCo Magnet

1.Very good coercive force.

2.Good temperature stability.

3.It has a strong resistance to corrosion and oxidation.

Disadvantage of SmCo Magnet

1.Susceptible to price fluctuations (metal cobalt market price sensitive).

2.The hardness and brittleness of SmCo magnet limits its processability,and compared to NdFeB magnets are easier to break.

|

|

Samarium cobalt magnet,because of its good thermal stability,high termperatrue capability and its superior resistance to corrosion,is very suitable for high performance permanent magnetic motors and magnetic suspension system.

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com