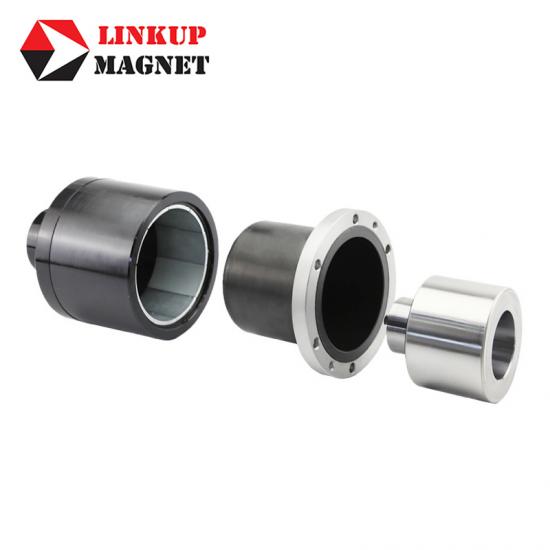

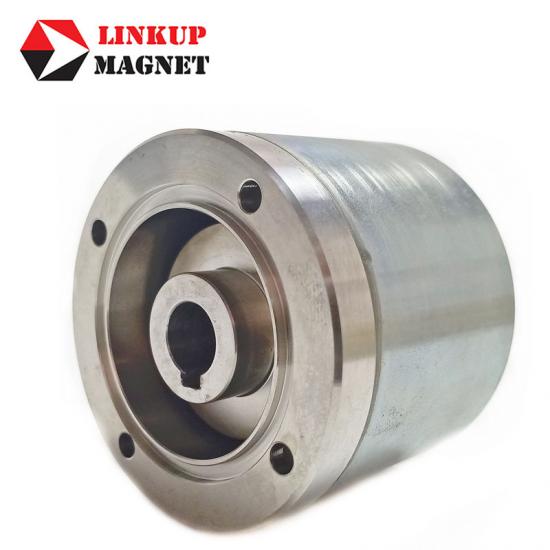

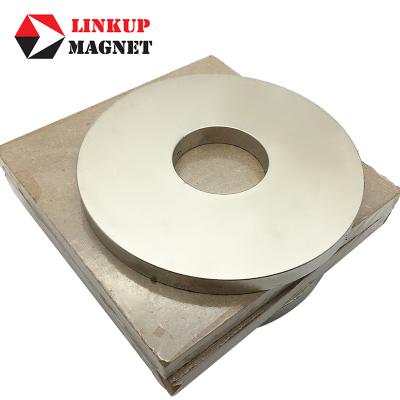

Non-contact synchronous couplings have a softer start and stop function than most standard couplings and can be used as a torque limiting device since there are no mechanically engaged parts.

Magnetic couplings has no auxiliary hydraulic and cooling systems,and no contact between the inner and outer rotors,which greatly reduces the difficulty and frequency of maintenance,reduces the cost of maintenance,reduces the number of shutdowns,and improves production efficiency.In case of pipeline blockage or pressure increase,this magnetic coupling has automatic overload protection,which effectively prevents dangerous situations such as overload explosion and pipeline rupture,and reduces the probability of accidents.

Application Of Magnetic Couplings

Magnetic Coupling can be used in a rotary configuration and are suitable for use in wet or harsh environments.Magnetic couplings are a common choice for mechanical applications including transmissions,pumps,compressors and assembly systems.

Specifications Of Magnetic Couplings

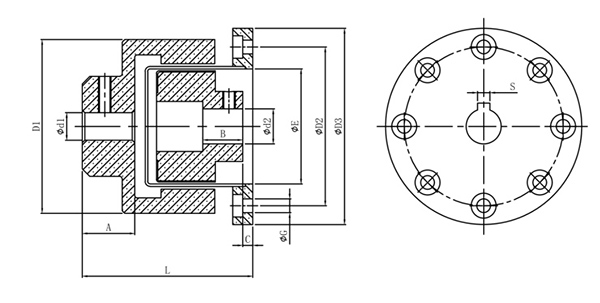

| Model | Torque (NM) | Size (mm) | |||||||||||

| A | B | C | D1 | D2 | D3 | d1 | d2 | E | G | L | S | ||

| LUMC46 | 1/3/5 | 21 | 16 | 5 | 69.5 | 63.5 | 78.5 | 11 | 14 | 46 | 5.5 | 69.5 | 5 |

| LUMC60 | 7/10/18 | 28 | 30 | 4 | 94.5 | 75 | 89.5 | 12 | 12 | 59 | 7 | 82 | 4 |

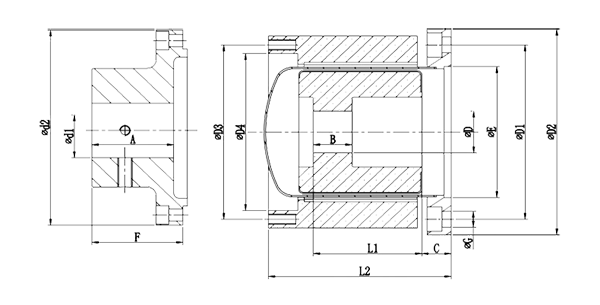

| Model | Torque (NM) | Size (mm) | Optional(mm) | |||||||||||||

| E | B | C | D | D1 | D2 | D3 | D4 | L1 | L2 | G | A | F | d1 | d2 | ||

| LUMC75 | 22/33/40 | 75 | 21 | 16 | 24 | 100 | 118 | 100 | 90 | 59 | 99.5 | 9 | 44.5 | 49.5 | 31.3 | 112 |

| LUMC110 | 62/80/110 | 110 | 20 | 25.5 | 35 | 133 | 153 | 135 | 126 | 66 | 108.5 | 9 | 55 | 65 | 38 | 148 |

| LUMC135 | 196/235/293 | 135 | 40 | 17.2 | 35.3 | 158 | 178 | 176 | 137 | 92 | 137 | 9 | / | / | / | / |

| LUMC145 | 200/250/300/410 | 146 | 50 | 24.7 | 45 | 180 | 205 | 196 | 150 | 108.5 | 167.2 | 11 | / | / | / | / |

| LUMC155 | 240/340/440/540 | 155 | 45 | 24 | 39 | 192 | 218 | 196 | 159 | 120 | 190 | 9 | / | / | / | / |

| LUMC200 | 610/760/820/1000/1200 | 198 | 48 | 34 | 50 | 232 | 258 | 258 | 202 | 160 | 218 | 11 | / | / | / | / |

Tel : +86-592-2069826

Tel : +86-592-2069826 E-mail : Sales@linkupmagnets.com

E-mail : Sales@linkupmagnets.com